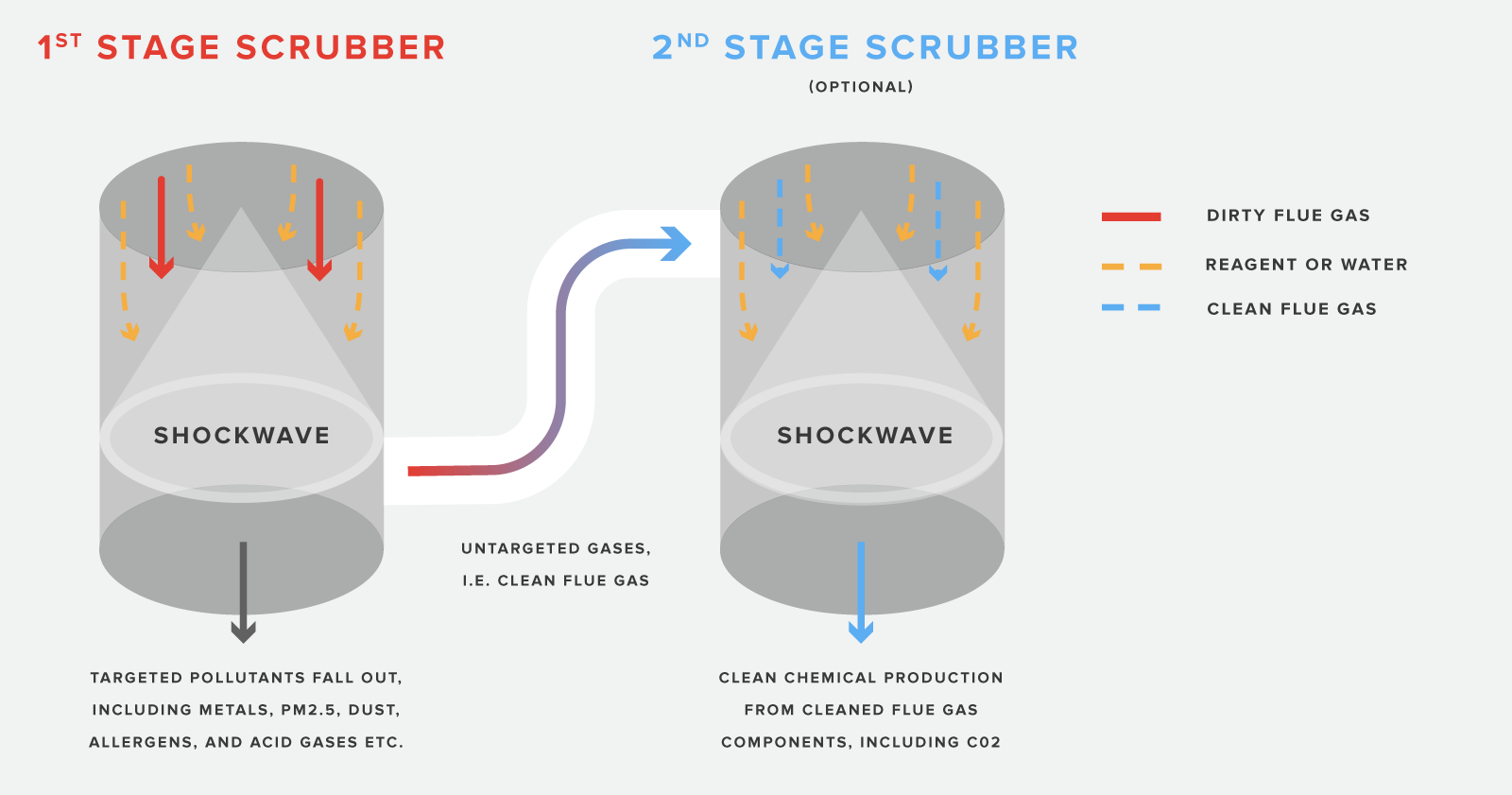

This “rocket science” technology can clean up to 99. 99%+ of any gas stream and reach nearly any level of compliance. Shockwave CO2 has authorized license of this technology to use in certain territory and markets.

MEAT SCRUBBER 8’ x 4’ x 4’

Small-scale shock scrubber is used in commercial applications, including scrubbing and cleaning for food application CO2 liquefaction and complete dust and PM removal

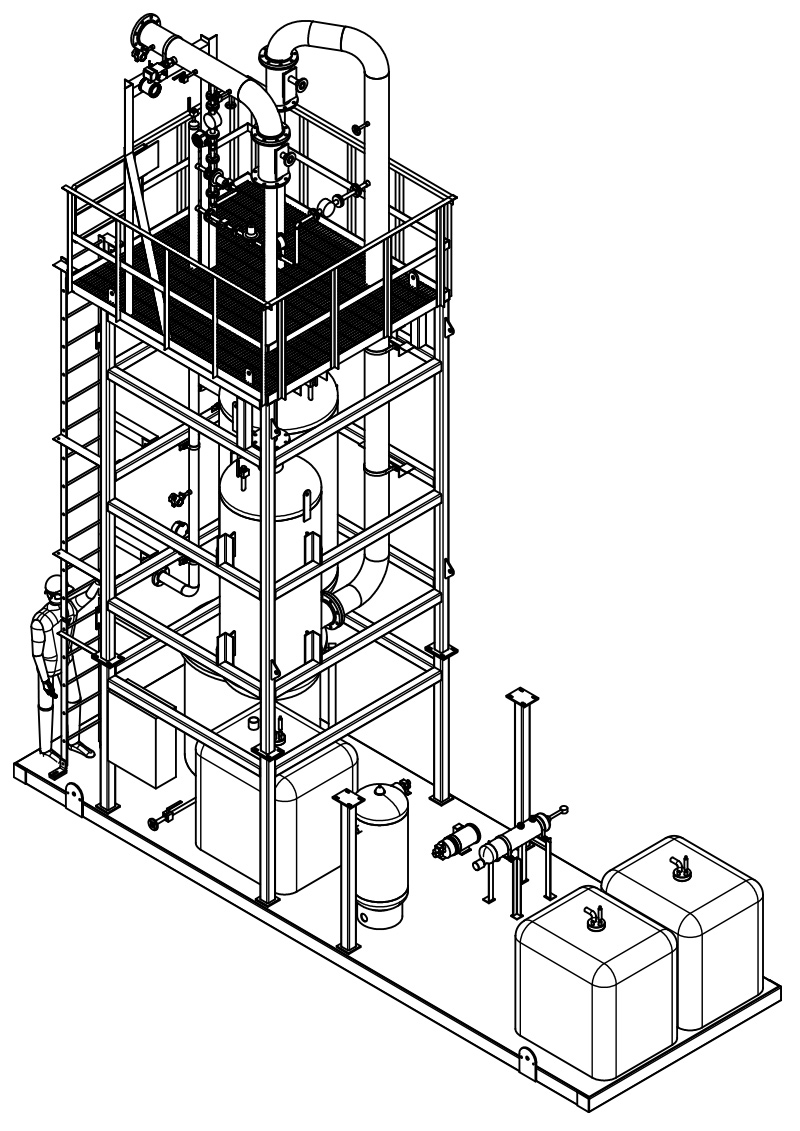

TOWER SKID 26’ x 8’ x 24’

Two-stage scrubber tower is used for small-scale industrial scrubbing applications where the first stage targets and removes solids and the second stage targets and removes acid gases

Industrial scrubber is designed for 25-35MWe coal-fired boiler retrofit or new build applications able to achieve total compliance for PM2.5, SOx, metals at significantly lower CAPEX and OPEX budget than traditional FGD and baghouse technology

PRODUCTION

Up to 50lbs/min of boiler exhaust = over 2 tons of CO2/day

FOOTPRINT

24’(L) x 8’(W) x 26’(H)

CHEMICALS

Common food-safe reagents NaOH (lye), Na2CO3 (soda ash), and water

SYSTEM LIFE

Over 20 years continuous industrial use without defect

SAFETY

No external heat, low noise, low pressure system, standard handling care of CO2

MAINTENANCE

No internal moving parts, simple chemical replenishment, simple instructions, pumps require routine annual service

CO2 PURITY

Beverage-grade CO2 (99.9% pure) by volume minimum