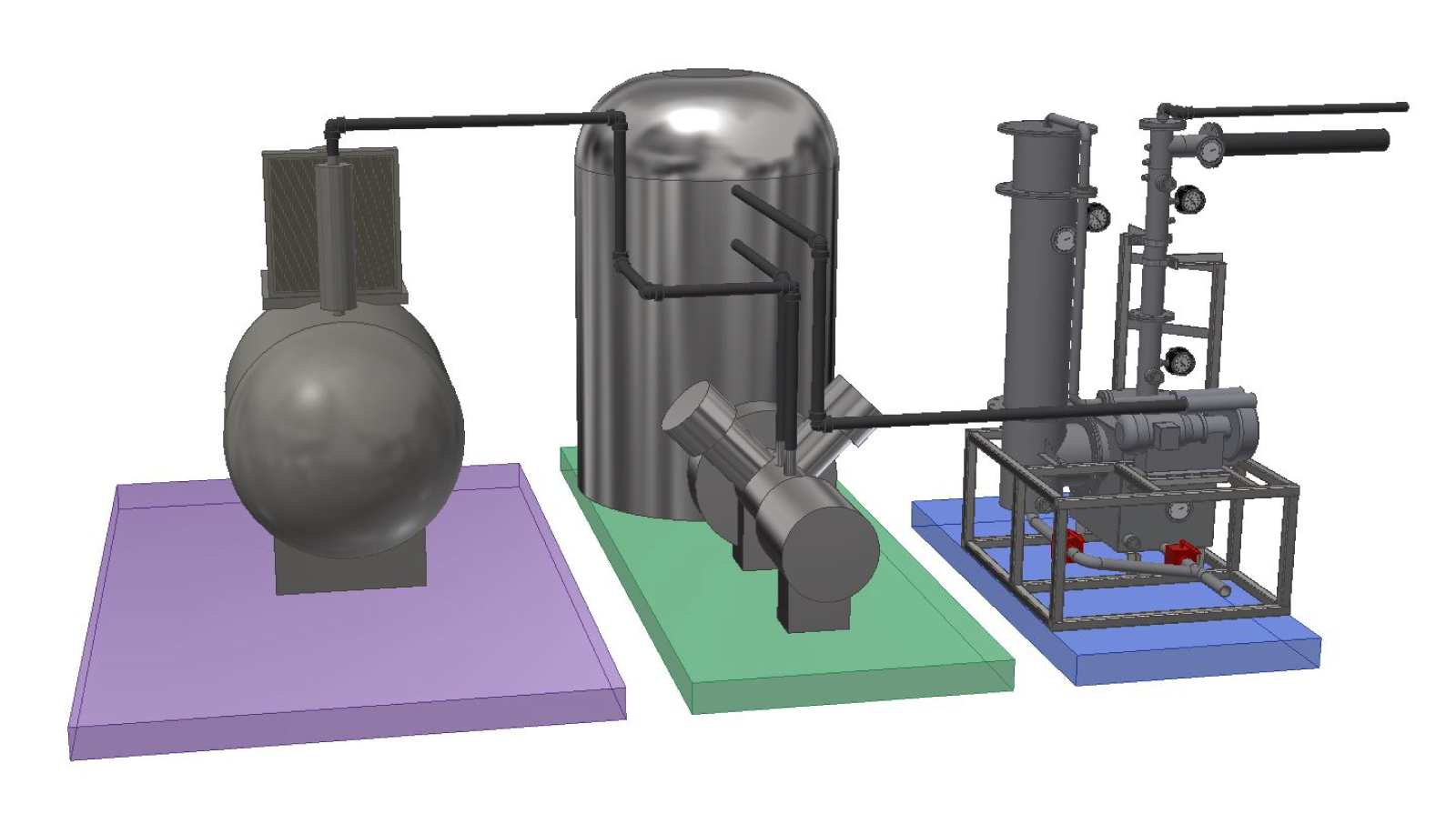

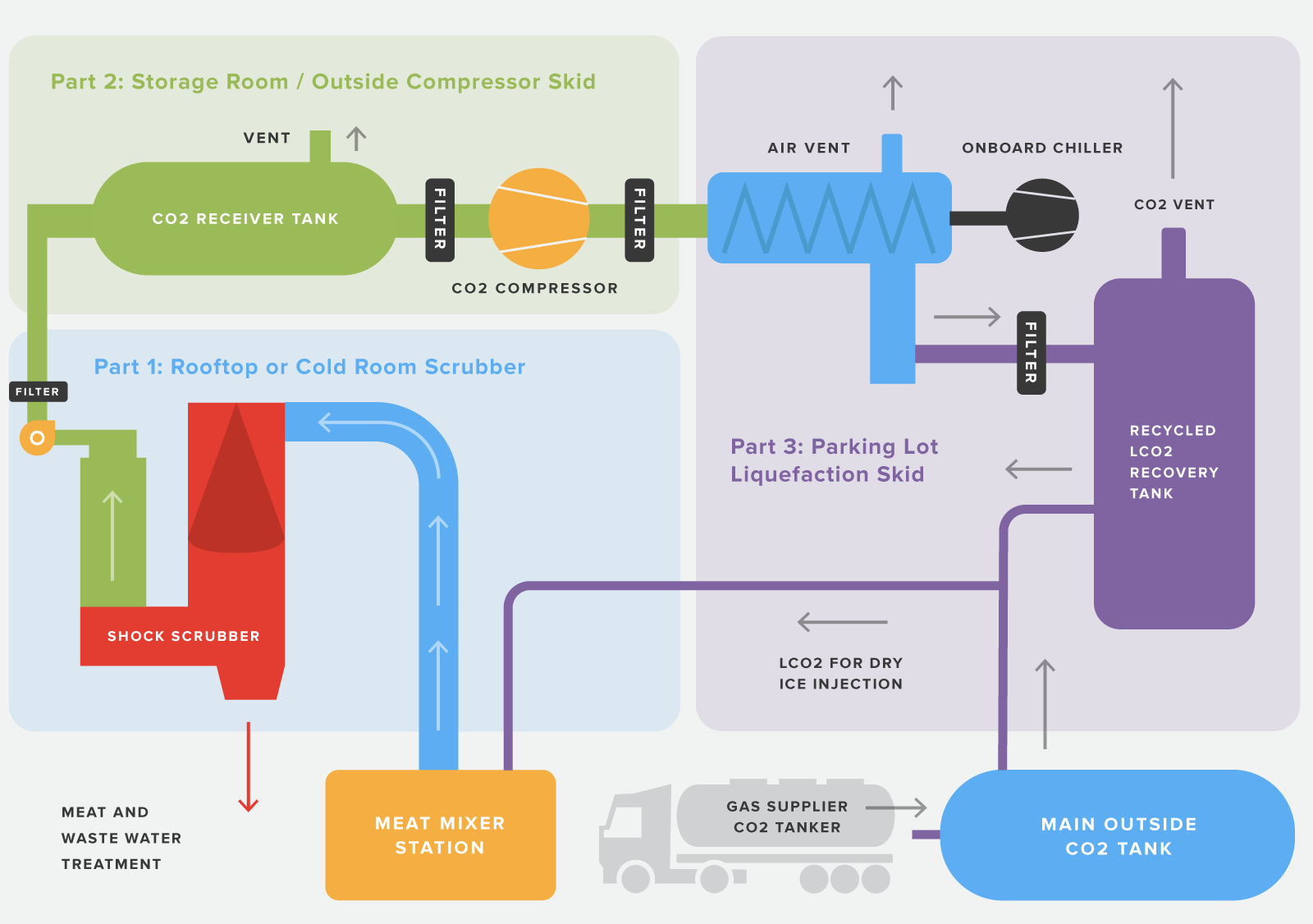

SW LCO2 system is a process developed for food & beverage applications and can be used for other applications as well. Food processes, such as dry ice injection or meat mixing, that spray CO2 for chilling purposes can vent their exhaust CO2 into our SW LCO2 system where we scrub clean, recover, and recycle the CO2 as food-grade liquid CO2 to return back into their storage tank.

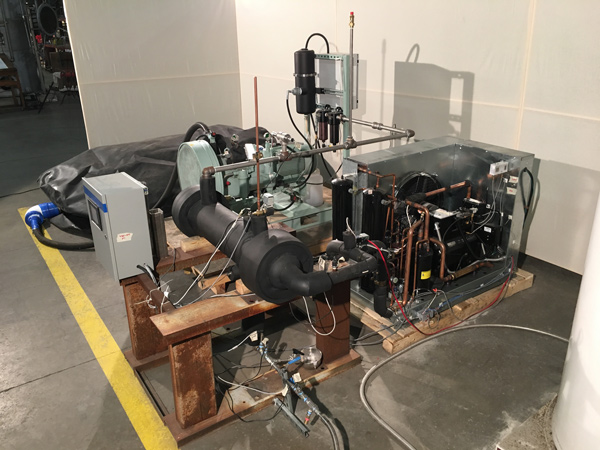

Shock Scrubbers are placed near or underneath meat mixing stations in cold rooms where they will remove all particles and odors from the CO2 stream. The cleaned CO2 will then be collected inside storage bags or tanks. Food-grade CO2 Compressors and Liquefiers will then liquefy the CO2 (“LCO2”). The LCO2 will then be separated from air and then pumped back into the tank ready for re-use as dry ice.

This method of onsite cleaning, collecting, and re-liquefying CO2 is extremely cost-efficient where customers can save a ton of money by using low-cost electricity to recycle high concentration, cold CO2 streams and skipping all the added processing, transportation, and logistics costs. Customers can expect to save as much as 50% on their monthly bill for the recovered CO2.