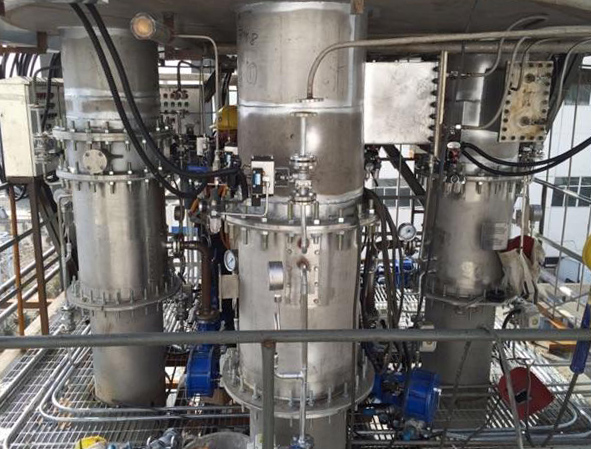

Simple, compact, and moveable systems to capture CO2 at low cost with emphasis on carbon re-use or sequestration. These systems are larger versions of the SW Chem Loop skid and can produce carbonate and bicarbonate products with a simple setup and low-cost equipment.

The mineralized products can be used for many commercial applications (or sequestered) or used to liberate and produce pure CO2 gas.

MAIN ADVANTAGES ARE:

- Low cost equipment, simple arrangement

- Applications for smaller users

- Easily scalable to larger sizes

- Conversion of CO2 into saleable products

- Can release pure CO2 gas from “desorbing” carbonate

- Can link with SW LCO2 system for liquid CO2 production

Shockwave offers standalone next-generation, high performance, portable scrubber systems to clean flue gas or exhaust gases of multi-pollutant emissions.

LOW-COST

Small and portable systems that take up little footprint and have no internal moving parts

High performance

Can achieve all levels of emissions compliance, including PM2.5, metals, SOx, and more (please ask about technology updates currently in development for other targeted emissions)

NOx testing

Currently underway and in development

All sizes available from small commercial usage

(i.e. clean room, hospitals) to industrial boilers

Shockwave currently offers three types of CO2 recovery systems.

Onsite, high performance system pairing shockwave scrubbers and a proprietary CO2 liquefaction (“LCO2”) process that cleans, recovers, and recycles high concentration (70-90%+) CO2 gas as food-grade liquid CO2 – this service was designed for the food & beverage industry to recover vented food-grade CO2 as recycled product at ultra-low cost and save food companies money.

Portable skid-based system using shockwave mixing and reusable chemicals to capture CO2 from waste emissions, including 8-25% CO2 from flue gas, or higher concentrations from hot stack gas sources, using minimal utility at very low cost to produce concentrated (99%+) streams of CO2 gas or soda ash and baking soda, or other upgraded chemical materials.

A variation of the SW Chem Loop system, this chemical looping system is designed for the greenhouse agriculture industry. From an onsite boiler or heater exhaust stack, this system selectively targets pollutants, including PM, metals, SOx, and NOx to make high quality liquid potassium fertilizers. The cleansed CO2 gas is left intact in the gas stream and is piped into the greenhouse to rapidly boost agriculture production.

Shockwave is pioneering two distinct systems that recover and convert solids from flue gas streams into marketable products

A shockwave scrubber system currently in development that scrubs coal-fired flue gas of all solids, including ash, dust, and PM, then neutralizes the slurry acid, and drains the solids to be used as roadway construction material.

Under future development, a shockwave scrubber paired with a metal separation technology that can capture, isolate, and recover ferrous and non-ferrous metals from a waste to be recovered by a steel mill as free high value raw material.